2025-12-02

Author: Bao Yazi (Senior Engineer)

Shenzhen Soway Tech Limited.

1. Overview

With the increasing prevalence of automation and the rapid development of intelligent automation in global industry, the use of sensors is increasing. The development of high-performance displacement sensors offers significant economic benefits. This article introduces a pen-shaped displacement sensor based on the differential transformer principle. It features high accuracy, reliable operation, and ease of use. It can be widely used in precision dimensional inspection, wheel roundness and flatness testing, and automotive glass sizing.

2. Working principle

Figure 1: LVDT Schematic

LVDT (Linear Variable Differential Transformer) is the abbreviation for Linear Variable Differential Transformer. Its working principle is simply a core-moving transformer. It consists of a primary coil, two secondary coils, an iron core, a coil bobbin, and a housing. When the core moves from the center to the sides, the difference in the output voltage of the two secondary coils is linearly related to the core movement. When an alternating voltage of a certain frequency is applied between the primary coils P1 and P2, the iron core moves inside the coil, changing the potential signal output in space, thereby changing the mutual inductance between the primary and secondary coil voltages. An induced electromotive force is generated between the secondary coils S1 and S2. As the position of the iron core changes, the amount of inductance also changes, and the induced electromotive force generated by the secondary also changes. In this way, the subsequent quantity of the iron core is converted into a voltage signal output. Due to the reconstruction of the secondary coil voltage, as shown in Figure 1, the output is a differential voltage.

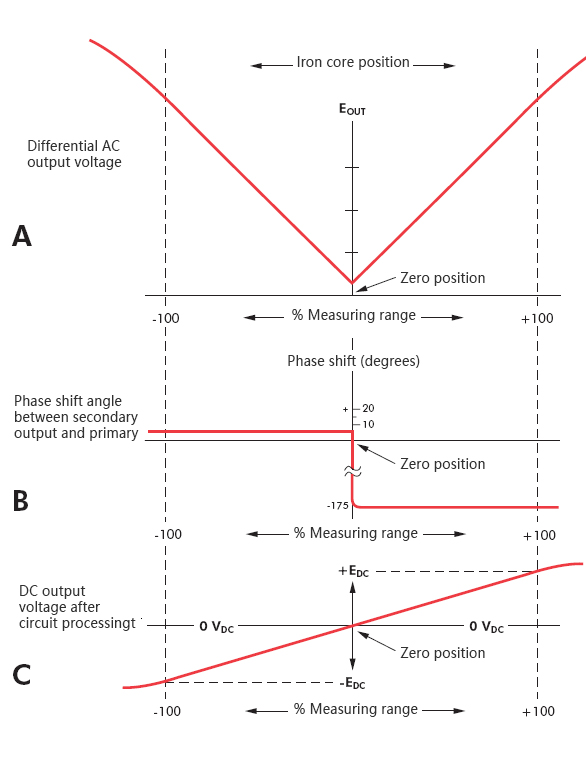

Figure 2: Output voltage of an LVDT

When the core moves rightward, the voltage induced by secondary coil S2 is greater than that of secondary coil S1. When the core moves leftward, the voltage induced by secondary coil S1 is greater than that of secondary coil S2. The difference in the voltage outputs of the two coils varies linearly with the core displacement. The dashed line in Figure 2 represents the sensor's measuring range. When the core travels greater than 100% (outside the dashed line), the linear relationship between the difference in the output voltages of the two secondary coils and core displacement deteriorates. The solid lines on either side of the zero point generally represent symmetrical measuring ranges, with both signals being AC with a 180-degree phase difference. In practical LVDTs, the coil is typically fixed to the housing as one piece, while the core and stem are fixed to a separate piece. Relative displacement between these two pieces generates a displacement voltage output.

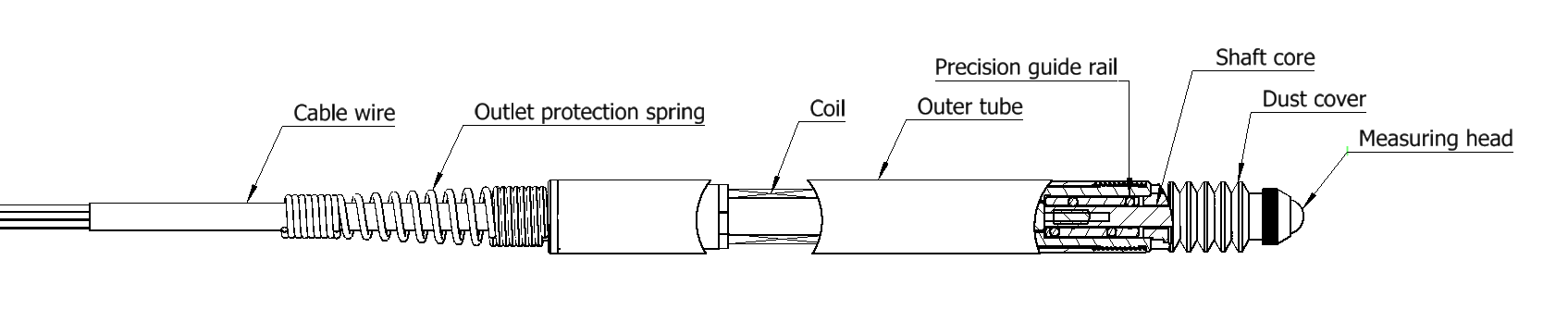

3. SDVH8-8 Pencil-Shaped Rebound LVDT Product Structure

The structure of the pencil-shaped LVDT product is shown in Figure

Figure 3: LVDT schematic

• Supply Voltage: 9-28V DC

• Output Signal: 0-5VDC, 4-20 mA , RS485 digital signal

• Frequency Response (-3dB): 20Hz (maximum), 50Hz (current output)

• Linearity Error (full-scale output): ≤±0.25% of FS

• Repeatability Error: <1µm

• Operating Temperature: -25°C to +85°C

• Temperature Coefficient: ≤0.025%/°C (rated)

LVDT has the following characteristics:

① Frictionless Measurement

An LVDT's moving core and coil typically have no physical contact, meaning it is a frictionless component. It is used for critical measurements that can withstand the loads of a lightweight core but cannot withstand friction. Examples include impact deflection or vibration testing of precision materials, and tensile or creep testing of fibers or other highly elastic materials.

② Infinite Mechanical Life

Because there is no friction or contact between the LVDT's coil and core, there is no wear. Therefore, the LVDT's mechanical life is theoretically infinite. This is a crucial technical requirement in applications such as fatigue testing of materials and structures. Furthermore, infinite mechanical life is crucial for high-reliability mechanical devices in aircraft, missiles, spacecraft, and critical industrial equipment.

③ Infinite Resolution

The LVDT's frictionless operation and sensing principle provide two notable characteristics. The first is truly infinite resolution. This means that the LVDT can respond to the slightest movement of the core and generate an output. The only limitation on resolution is the difference in external electronics.

④ Zero Position Repeatability

The LVDT has a simple construction and a resettable zero position. The LVDT's electrical zero position is highly repeatable and extremely stable. In closed-loop control systems, the LVDT offers excellent electrical zero position instantaneity.

⑤ Radial Insensitivity

The LVDT is highly sensitive to axial core movement and relatively insensitive to radial movement. This allows it to measure objects that do not follow a precise linear motion. For example, it can be coupled to the end of a Bourdon tube to measure pressure.

⑥ Input/ Output Isolation

The LVDT is considered a transformer because its excitation input (primary) and output (secondary) are fully isolated. The LVDT does not require a buffer amplifier and can be considered an effective analog signal element. It is particularly useful in measurement and control circuits where signal lines must be isolated from the power ground.

⑦ Ruggedness

The materials used to manufacture the LVDT and the processes used to join them make it a rugged transmitter. Even under the severe shock and vibration common in industrial environments, the LVDT continues to function. Separated Core and Coil LVDTs have separate cores and coils. A non-magnetic spacer is inserted between the core and the inner wall of the coil to isolate pressurized, corrosive, or alkaline fluids from the coil assembly. This creates a hermetic seal around the coil assembly, eliminating the need for dynamic sealing of moving parts. For coil assemblies in pressurized systems, static seals are sufficient.

⑧ Environmental Adaptability

LVDTs are one of the few transmitters that can operate in a variety of harsh environments. For example, sealed LVDTs, with their stainless steel housings, can be placed in corrosive liquids or gases. Sometimes, LVDTs are required to operate in extremely harsh environments, such as cryogenic environments like liquid nitrogen or in nuclear radiation environments. While in most cases, LVDTs have an unlimited operating life (theoretically), the operating life of LVDTs placed in harsh environments varies depending on the environment.。

6. Application Examples of SOWAY Products

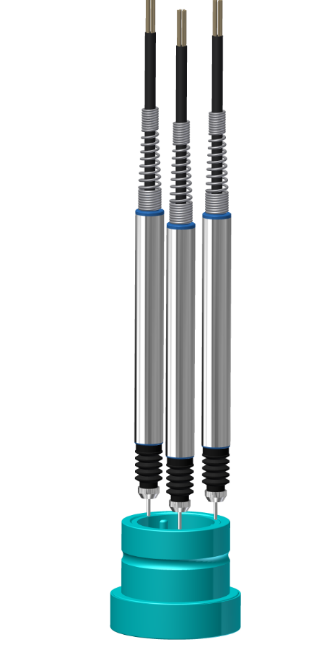

Flatness test: Our company produces SDVH8-8 rebound LVDT used in plane flatness measurement, with a repeatability of 1um.

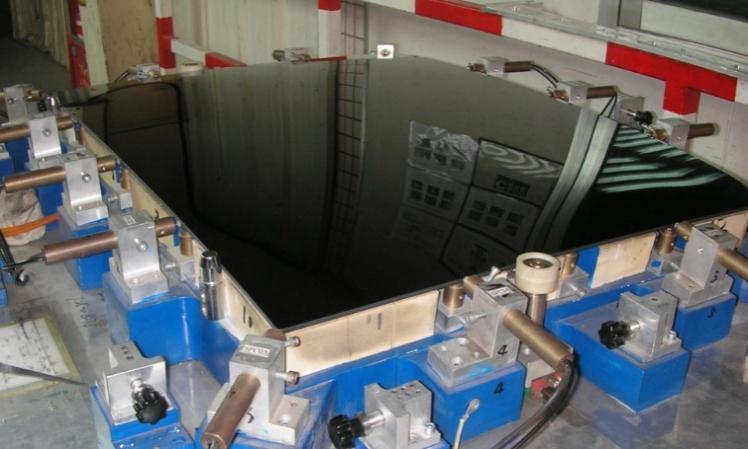

Automotive glass production: Since automotive glass is a curved surface, multi-point measurement is required when measuring the product quality, such as the external dimensions and the dimensions of the curved surface. Our company's SDVN8-8 pneumatic LVDT is used to measure the curved surface of automotive glass. It can measure 20 to 60 points at the same time with high measurement accuracy and a repeatability of 1um.

Parts assembly position detection: Our company's SDVH8-5 rebound LVDT is used in bearing or other parts assembly measurement with a repeatability of 1um.

Axis detection: Our company produces SDVH8-5 rebound LVDT which is used in the measurement of axis parameters with a repeatability of 1um.

LinkedIn: https://www.linkedin.com/company/31762526/admin/dashboard/

Facebook: https://www.facebook.com/SowayTechLimited/

Instagram: https://www.instagram.com/sowaysensor/

Company Name: Soway Tech Limited

Contact Person: Fanny Fan

Email: fanny@sowaysensing.com

Telephone: +86 - 13632581427

Address: No.28 Xinfeng Road Potoubei Ailian Longgang Shenzhen China 518172

Website: www.sowaysensing.com

Disclaimer: This article is reproduced from other media. The purpose of reprinting is to convey more information. It does not mean that this website agrees with its views and is responsible for its authenticity, and does not bear any legal responsibility. All resources on this site are collected on the Internet. The purpose of sharing is for everyone's learning and reference only. If there is copyright or intellectual property infringement, please leave us a message.

©copyright 2009-2020 Zao Bao Daily Contact Us SiteMap